Review of 2015 Trends in Fluid Catalytic Cracking Patents, Part I: Catalyst Additives

Feb 25th, 2016 by William Reid | News | Recent News & Articles |

This is the first article in a review of patents issued in 2015 in the area of Fluid Catalytic Cracking (FCC). The summary below covers five patents relating to FCC catalyst additives. These include: two related to gasoline sulfur reduction catalysts; two related to metals deactivators/traps; and a ZSM-5 additive patent. Review of this collection of patents illustrates a somewhat subdued activity in additive research activity for the FCC, at least that devoted to patentable activities. To be fair, there are almost double the number of “catalyst” related patents, and some of these are directed to olefin production, which would boost the number in the olefin/octane area. These will be summarized next month. For the sulfur reduction and metals trapping areas, time will tell whether there is a resurgence in these areas.

U.S. Patent No. 8,927,451 describes a sulfur reduction additive system. The additive contains separate particles of an FCC catalyst and a porous montmorillonite clay. The cracking catalyst can contain a zeolite, a non-zeolite molecular sieve, a catalytically active amorphous silica alumina species or combinations thereof. The cracking catalyst can also contain matrix components such as clays, modified clays, alumina’s and catalyst binders such as inorganic oxide sols or gels. The patent is related to predecessors U.S. 8,623,199 and U.S. 8,409,428, and shares a priority provisional patent application, U.S. Appl. No. 61/137,471, with U.S. 9,211,525, discussed below.

U.S. Patent No. 8,932,712 describes a metal passivator additive containing: 1 to 50 wt% of a rare earth component; 5 to 30 wt% of alumina; 10 to 50 wt% clay; 2 to 15 wt% colloidal silica; and 1 to 10 wt% of a zeolite having a silica/alumina ratio of more than 8. The alumina is pseudoboehmite alumina, gel alumina, bayerite and gamma alumina or mixtures thereof. The colloidal silica includes aqueous colloidal dispersions of silica particles, stabilized by small quantities of sodium hydroxide or ammonium hydroxide. The zeolites are large pore materials obtained from faujasite with residual soda about 13 wt% repeatedly exchanged with an ammonium salt such as ammonium sulphate, ammonium nitrate, ammonium chloride and ammonium acetate till residual soda is below 3 wt%. The zeolite is steamed to remove frame work aluminum, such that the residual soda is less than 0.8 wt%.

U.S. Patent No. 9,029,291 describes a metals (particularly vanadium and nickel) passivator/trap containing 5% rare earth oxide dispersed in a matrix containing a calcined hydrous kaolin. The matrix is essentially inactive for catalytic cracking.

U.S. Patent No. 9,067,196 describes a ZSM-5 containing additive, where the claim recites as a limitation the pH of the spray dryer feed material (5 to 9) and the additive acidity. Specifically, the additive also contains 40 to 60 wt%, P2O5 in the range of 7 to 12 wt% (from particular phosphate sources), clay in the range of 20 to 40 wt%, and binder in the range of 10 to 40 wt%, where the binder is 75 to 100 wt% silica, the silica content of the additive is above 70 wt%, the sodium content is less than 0.5 wt%

U.S. Patent No. 9,211,525 describes a sulfur reduction additive having a Group IIIA metal component (especially gallium), deposited on a montmorillonite clay, and a cracking catalyst. The cracking catalyst can contain a zeolite, a non-zeolite molecular sieve, a catalytically active amorphous silica alumina species or combinations thereof. The cracking catalyst can also contain matrix components such as clays, modified clays, alumina’s and catalyst binders such as inorganic oxide sols or gels. The patent shares a priority provisional patent application, U.S. Appl. No. 61/137,471, with U.S. 8,927,451, discussed above.

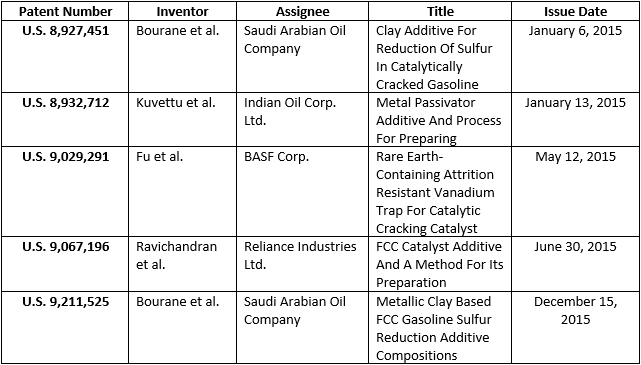

Table 1

FCC Patents — Catalyst Additives

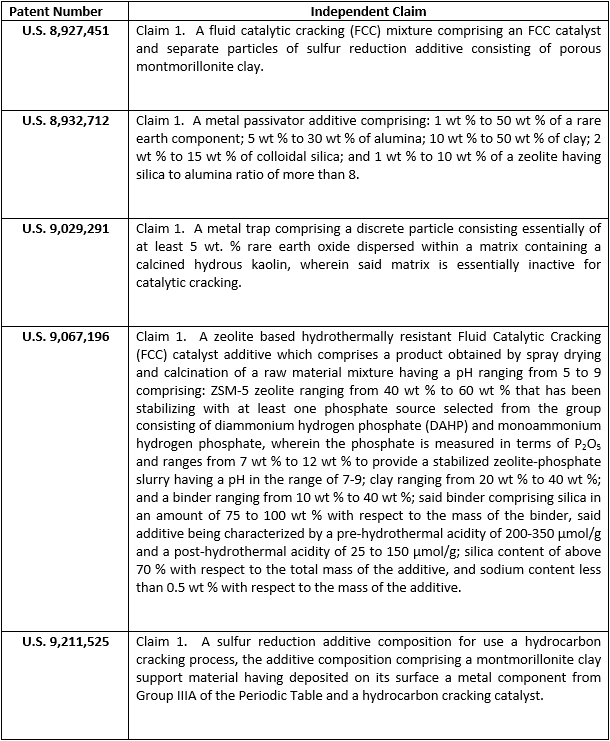

Table 2

FCC Catalyst Additives

My thanks to Mr. Ken Peccatiello of Peccatiello Engineering (www.PeccatielloEngineering.com) for reviewing the text.

This article is for informational purposes, is not intended to constitute legal advice, and may be considered advertising under applicable state laws. The opinions expressed in this article are those of the author only and are not necessarily shared by Dilworth IP, its other attorneys, agents, or staff, or its clients.