Recent Trends in Enhanced Oil Recovery Patents (2014), Part 2: Additives – Demulsifiers

Oct 6th, 2015 by William Reid | News | Recent News & Articles |

This is the second article in a series reviewing 2014 patents focused on Enhanced Oil Recovery (EOR). The initial article (see HERE) reviewed the area of Microbial Enhanced Oil Recovery, which concerns the use of microbes to extract oil from oil-containing formations. This and the next few articles relate to patents directed to chemical additives used in the EOR process. This is the case since there are a large number of patents related to EOR additives, so they will be divided into several sections and reviewed separately. In particular, this article will deal with patents directed to demulsifiers.

Chemical methods of EOR recovery generally include polymer flooding, chemical flooding, liquid carbon dioxide flooding, and hydrocarbon displacement. Additives used in this area employ a variety of mechanisms, e.g., a reduction in the oil-water interfacial tension, alteration of surface wettability, and the use of high viscosity agents for mobility control. The objective is generally to increase the mobility of the oil phase relative to the water used in flooding the well to maximize oil recovery. To improve operability and performance, EOR applications sometimes use a combination of surfactant and polymer, known as “SP” formulations and alkaline, surfactant and polymer systems, known as “ASP” formulations.

The SP or ASP systems are often complex systems, particularly designed for the crude of interest and the geology of the wellbore, and are very effective, however, in enhanced oil recovery processes, emulsions can form (oil in water or water in oil). Ultimately the emulsified oil/water stream must necessarily be “demulsified” back to oil and water streams, to maximize oil recovery, and minimize oil contamination of the water that is returned to the environment.

Review of recent patents in the demulsifier area reflect a corresponding complexity. One of the patents, (U.S. 8,697,615), is directed to systems containing polyepihalohydrins. U.S. 8,779,012 is directed to a demulsifying composition containing at least one polyorganosiloxane compound. U.S. 8,741,130 is directed to a process for resolving emulsions using a composition comprising a cationic surfactant containing one or more bolaform surfactant and one or more gemini surfactants. U.S. 8,911,615 generally relates to a method for demulsifying oil and water with a composition containing a combination of a cationic alkyl ammonium halide surfactant and an amphoteric betaine surfactant comprising cocoamino-propionic acid.

Enhanced Oil Recovery demulsifier patents are summarized below. Attached Table 1 lists relevant information on the demulsifier patents reviewed. Table 2 contains a representative independent claim from each.

Demulsifiers

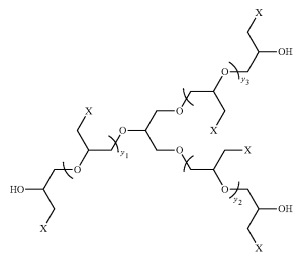

U.S. Patent No. 8,697,615 generally relates to compositions for breaking reverse emulsions, i.e., reverse oil emulsions or oil-in-water emulsions. The compositions include a particular class of polyepihalohydrins (see claim 1 for the structure), with preferred polyepihalohydrins being polyepichlorohydrin, polyepibromohydrin and polyepiiodohydrin. The polyepihalohydrins can be used in emulsions from an alkali-surfactant-polymer or surfactant-polymer enhanced oil recovery flood.

U.S. Patent No. 8,741,130 generally relates to a process for resolving emulsions produced in an enhanced oil recovery process. The process uses a cationic surfactant containing one or more bolaform surfactant and one or more gemini surfactants. Bolaform surfactants have two hydrophilic groups and one hydrophobic group, with the two hydrophilic groups generally being at both ends of a non-polar chain. Gemini surfactants have two hydrophilic and two hydrophobic groups, and generally are amphiphilic, having two hydrocarbon tails and two ionic groups linked by a spacer which may be C2-C12.

U.S. Patent No. 8,779,012 generally relates to a demulsifying composition containing an oil phase an aqueous phase and at least one polyorganosiloxane compound (see claim 1 for the structure).

U.S. Patent No. 8,911,615 generally relates to a method for demulsifying oil and water with a composition containing a combination of a cationic alkyl ammonium halide surfactant and an amphoteric betaine surfactant comprising cocoamino-propionic acid. The composition contains 100 ppm to 20,000 ppm of cationic alkyl ammonium halide surfactant, where the halide of the cationic alkyl ammonium halide surfactant doesn’t comprise chlorine.

Table 1.

EOR Patents – Demulsifiers

| Patent Number | Inventor | Assignee | Title | Issue Date |

| U.S. 8,697,615 | Tekavec et al. | Nalco Company | Polyephihalohydrin Reverse Emulsion Breakers | April 15, 2014 |

| U.S. 8,741,130 | Nguyen et al. | Nalco Company | Method For Resolving Emulsions In Enhance Oil Recovery Operations | June 3, 2014 |

| U.S. 8,779,012 | Phukan et al. | Momentive Performance Materials Inc. | Biodegradable Polyorganosiloxane Demulsifier Composition And Method For Making The Same | July 15, 2014 |

| U.S. 8,911,615 | Rancy et al. | William Marsh Rice University | Recovery And Separation Of Crude Oil And Water From Emulsions | December 16, 2014 |

Table 2.

Enhanced Oil Recovery — Demulsifiers

– Bill Reid

Check out Bill’s bio page

This article is for informational purposes, is not intended to constitute legal advice, and may be considered advertising under applicable state laws. The opinions expressed in this article are those of the author only and are not necessarily shared by Dilworth IP, its other attorneys, agents, or staff, or its clients.